As the sole UK agents for FAMA we are able to offer a range of both ‘plug and play’ and bespoke solutions for your swarf management needs.

Their innovative patented technology, produces systems to help companies achieve environmental goals and increases in energy savings and more ecological production practices.

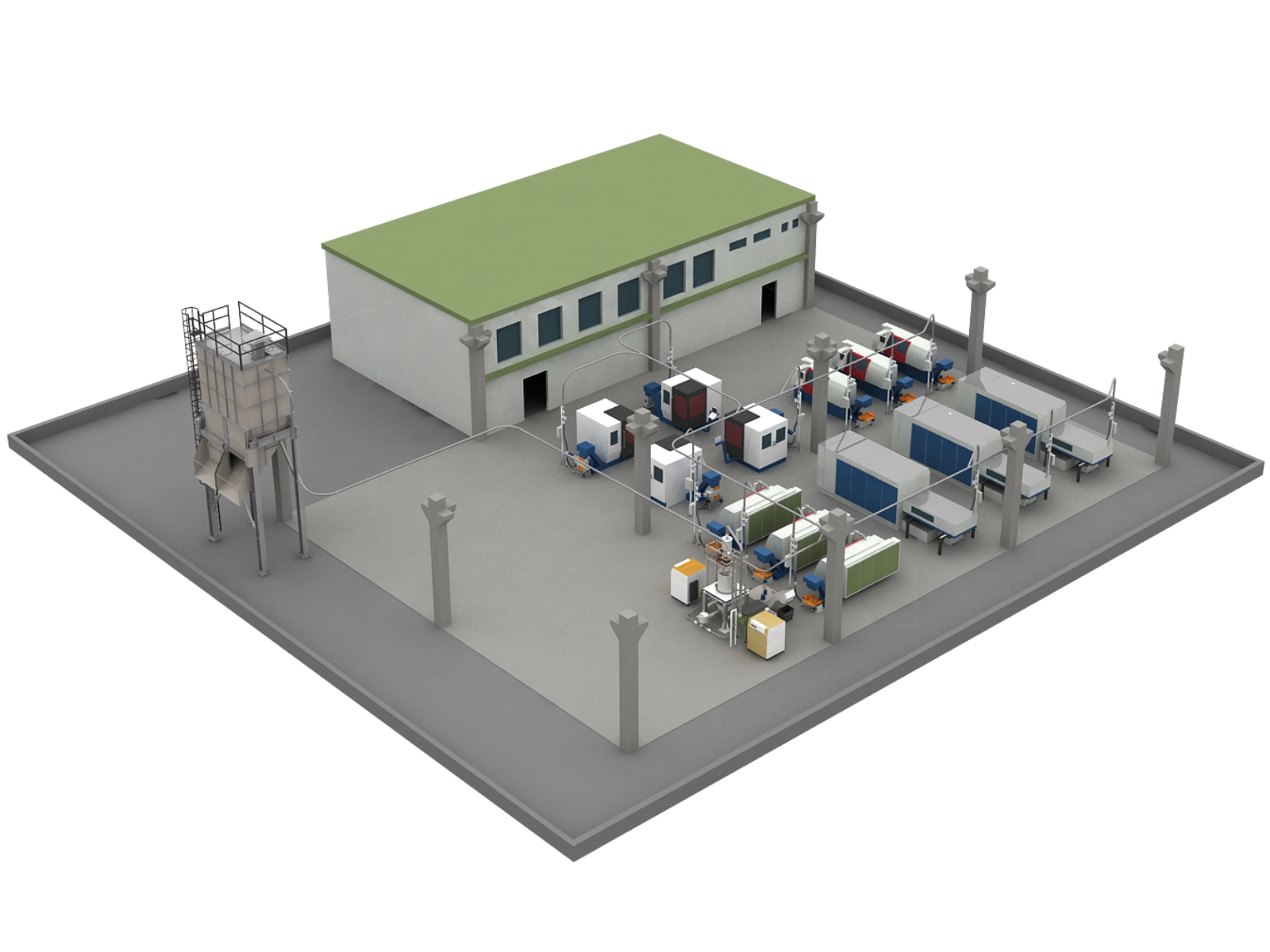

Bespoke systems are designed and built by FAMA Italy to manage the removal and recycling of swarf chips, reclaim oil and coolant efficiently and reduce swarf volume.

An overview of FAMA can be found here.

Our offering is split into the following four groups:

Compact centrifuge swarf treatment units

FAMA offers a range of standardised fully automatic swarf processing solutions or ‘treatment groups’ for metal swarf treatment, handling and crushing.

One unit we offer is the compact Calibri system separates chipped metal swarf from coolant using a centrifuge & stores the reclaimed coolant in an integrated self-cleaning storage tank.

The ‘plug & play’ unit is delivered ready to use as soon as its positioned & unwrapped!

Full details of the Calibri can be accessed via their website here.

Or alternatively viewed in their brochure.

Bespoke systems are available and we offer a full consultancy service from design through to delivery and installation

Please contact us to discuss your requirements.

Custom swarf treatment centrifuge systems

Bespoke swarf processing systems are available and we offer a full consultancy service from design through to delivery and installation

Please contact us to discuss your requirements.

Centralised oil & coolant filtration and redistribution systems

For customers looking to recycle and reuse their machine cutting oil and coolant, it is an important consideration that the efficiency and performance of their tooling machines is maintained by ensuring adequate treatment and filtration / micro filtration of these lubricants.

We offer highly specialised, customised, designed and built centralised systems for the treatment and filtration of used machine oil and coolant with workshop recirculation for lubricant reuse.

Available in various capacities, the collection tanks are fitted with self-cleaning filtration systems for filtration and micro filtration to produce oil or coolant free from metal swarf chips and sludge.

The filtered coolant or oil can be recirculated to machines / machining centres around a customer’s factory with options for automatic or manual re-filling systems.

As all systems are bespoke and we offer a full consultancy service from design through to delivery and installation

Please contact us to discuss your requirements.

Pneumatic swarf transport systems

Full info coming soon but in the meantime please contact us for details.