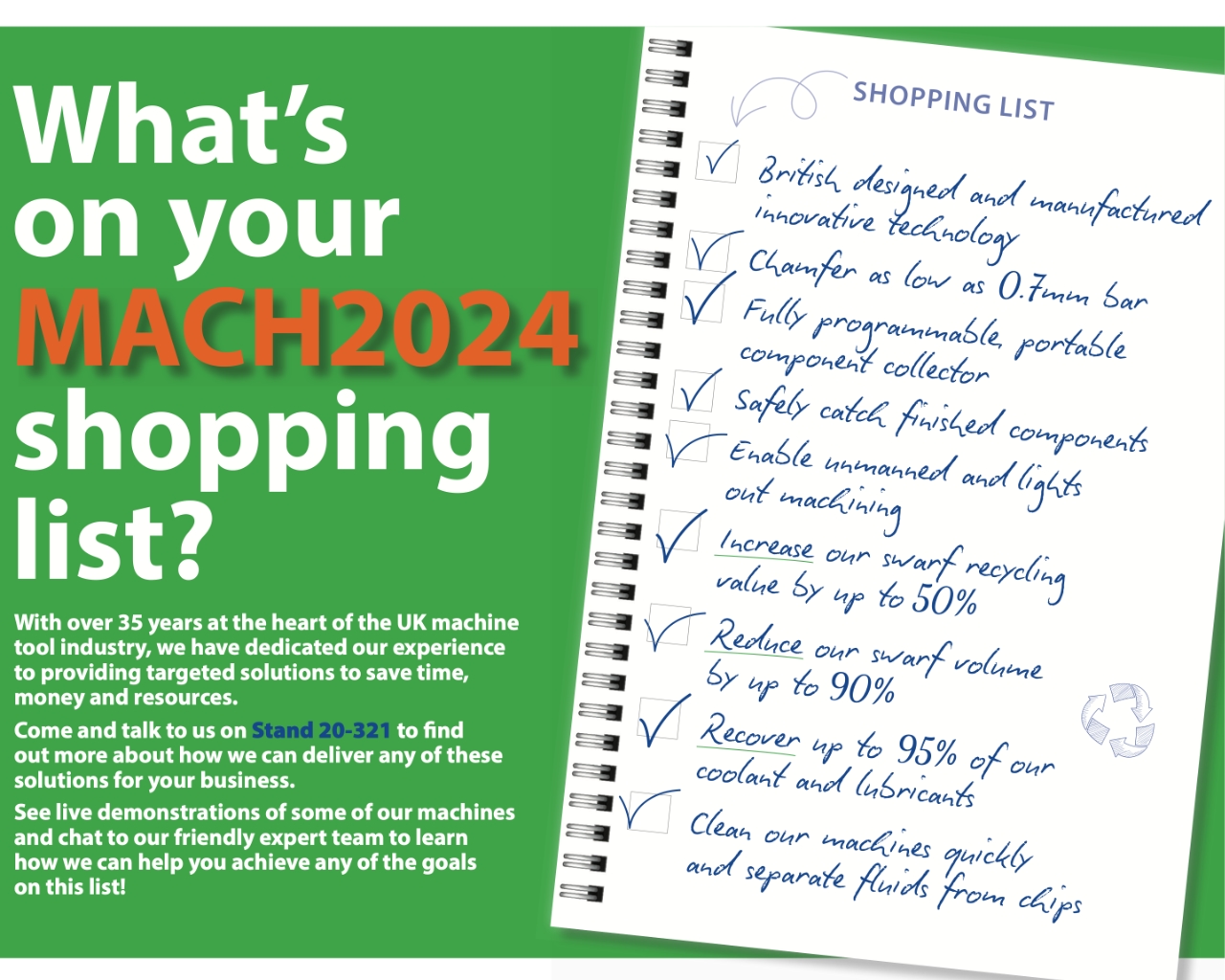

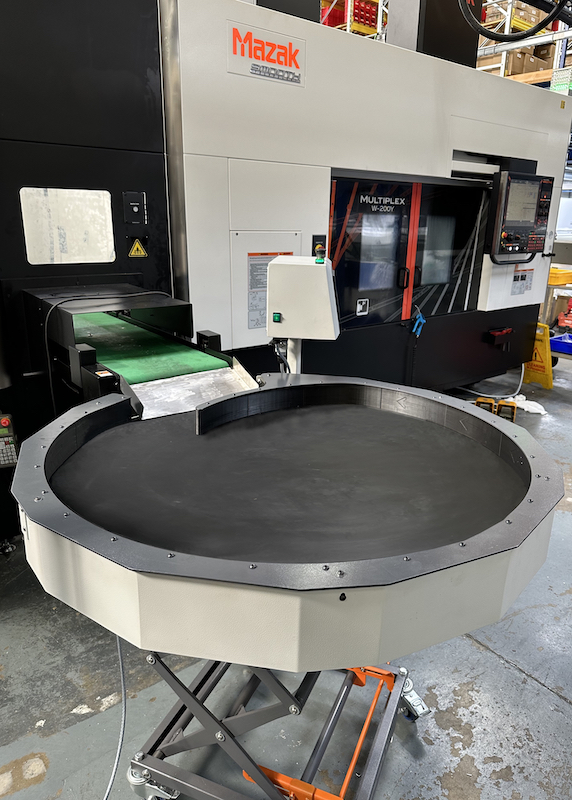

J&S Engineering MACH 2024 Hall 20 Stand 321 This year J&S Engineering are asking ‘What’s on your shopping list for MACH 2024?’ Exhibiting an exciting range of machinery from our product offering, J&S are looking to demonstrate to both end users & OEM’s alike the benefits of swarf processing, oil and coolant reclamation, bar chamfering …

Continue reading “J&S Engineering are asking ‘What’s on your MACH2024 shopping list?’”